Makerspace: Professor Aims to Help Students Succeed by Failing

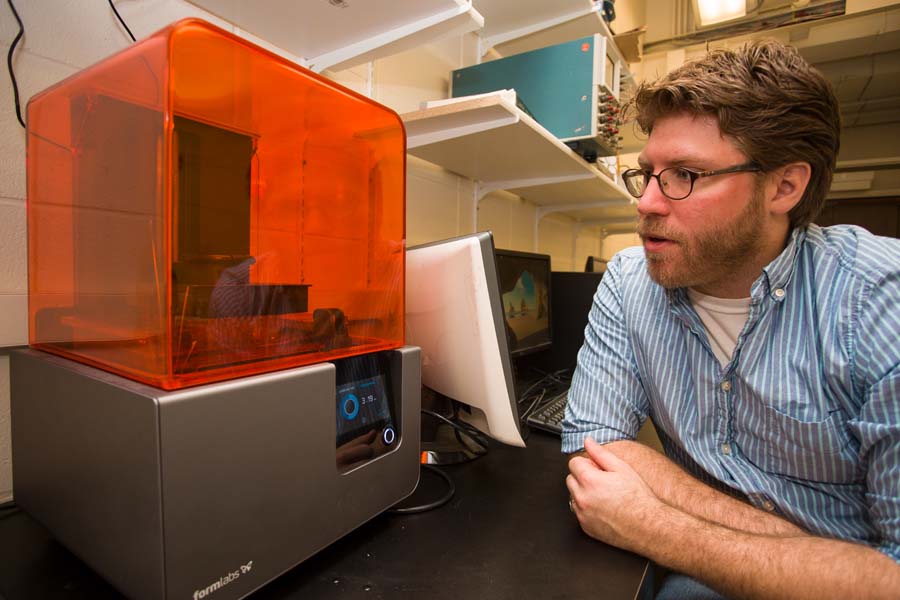

With new 3D printer, laser cutter, CNC mill, you can "fail early and often, and quickly learn from your mistakes."

Knox's "Science Makerspace" Resources:

- Boss Laser Cutter LS-4055—Focused laser head, capacity 48"x36" up to 1 inch thick (acrylic)

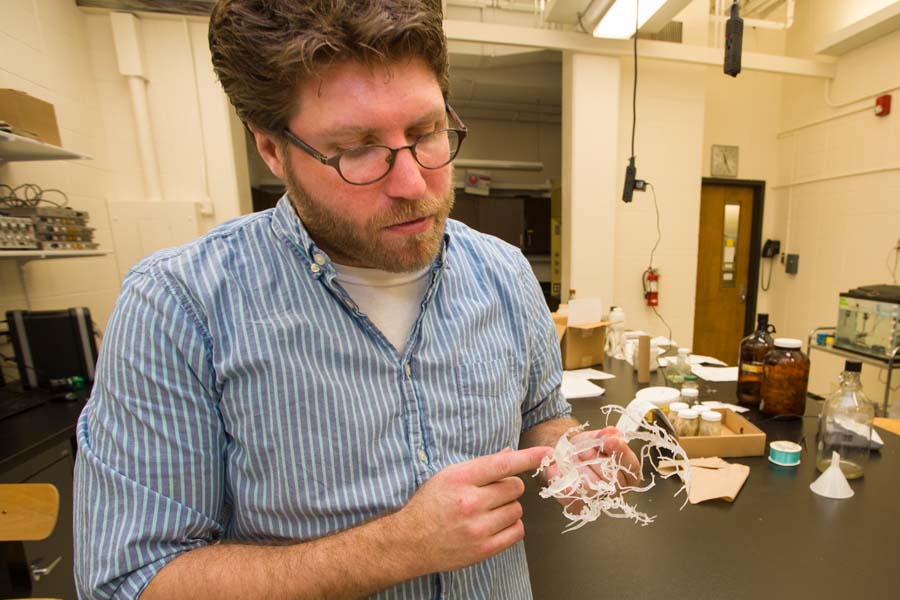

- FormLabs 3D Printer F2—Stereolithography process (laser cured polymer), resolution to 140 microns

- Tormach CNC Mill PCNC 770—Metal, wood, or acrylic; digitally-driven via Autodesk Fusion 360

Published on May 01, 2017